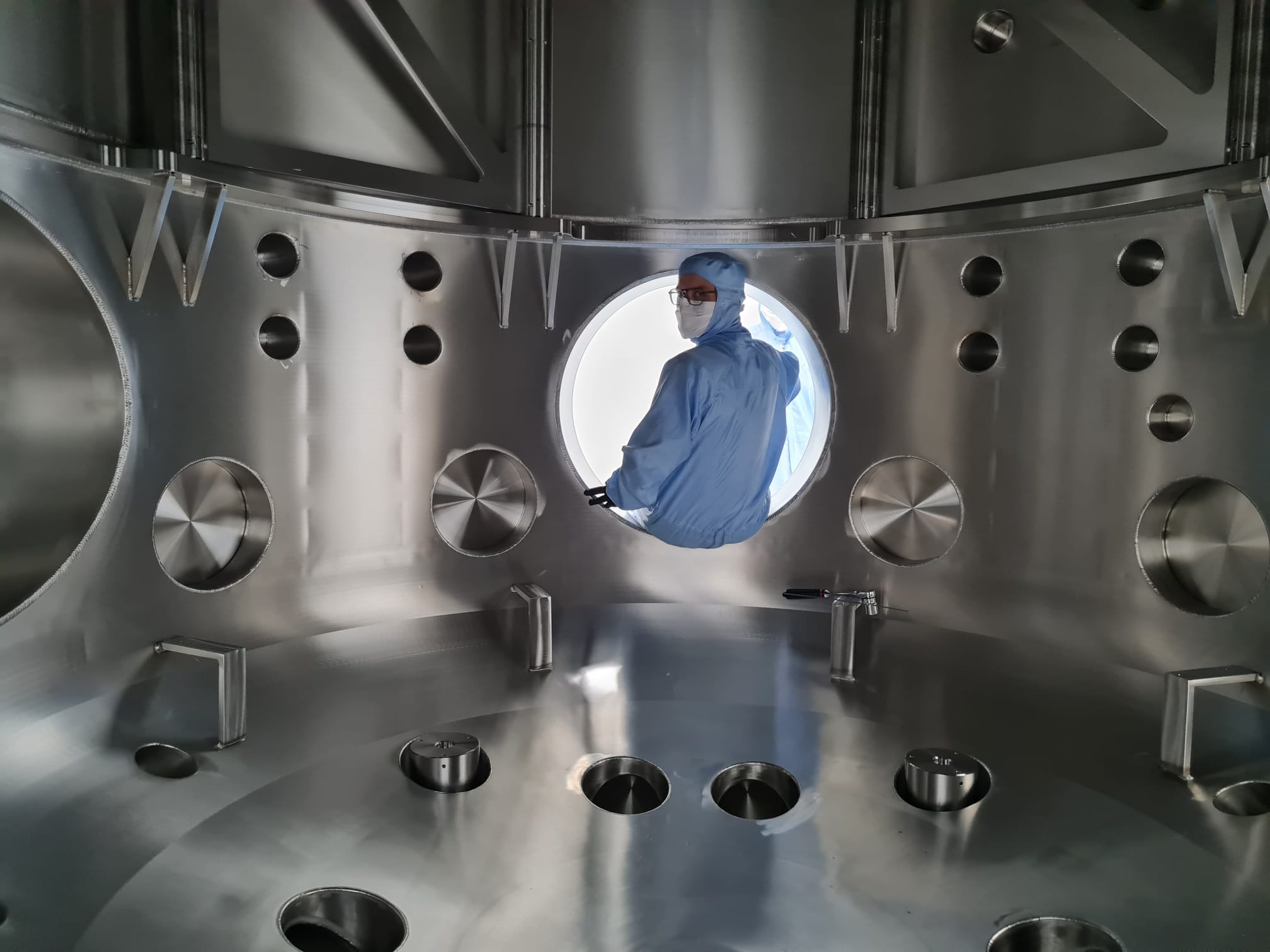

Nikhef, the national institute for subatomic physics in Amsterdam, approached Meilink Precision Cleaning, part of Meilink, last May to submit a proposal for high precision cleaning of components for the ETpathfinder. This is an R&D infrastructure being built to test and develop technology for the Einstein Telescope, the world's first of a new generation of observatories for gravitational waves. This requires absolutely particle-free components, which is why Nikhef was quick to choose Meilink Precision Cleaning.

Choice of Meilink Precision Cleaning

For this prestigious project, Nikhef had approached several parties in the market, but in no time, Meilink Precision Cleaning received the order for cleaning parts that were within reach of Meilink Precision Cleaning's facilities. Operations Manager Hans Cools says, "It is of course fantastic when you are asked for such a large project. With the ETpathfinder, technology is being developed that makes it possible to capture the sound of the formation of black holes or neutron stars. To be allowed to play even a small role in this, we first carefully conducted some tests in cooperation with Nikhef. From April '23, we started to clean and cleanroom package the components. By now, our part of the project has been completed to our complete satisfaction."

"After some market research, we quickly came to Meilink Precision Cleaning as one of the big names in the field of cleaning in and around the Netherlands."

Mathijs Baars, Design Engineer Nikhef

Engaged collaboration

As far as Nikhef project leader Mathijs Baars is concerned, Meilink Precision Cleaning has certainly lived up to its name as an expert. Mathijs: "After some exploratory market research, we quickly came to Meilink Precision Cleaning as one of the big names in the field of cleaning in and around the Netherlands. From the beginning of the project, Meilink Precision Cleaning was able to advise us on a number of issues and also helped us in a flexible and efficient manner with the required RGA (Rest Gas Analysis) tests."

"The process we experienced at Meilink Precision Cleaning was professional and organized. All the parts we delivered came back to us double wrapped in neat boxes within a few weeks, with no further problems or disruptions in deliveries. The cleaning work was well priced and we had absolutely nothing to complain about in terms of quality delivered! "

Connecting to the customer

Hans Cools: "Of course demonstrably good cleaning was a requirement. We did RGA tests for that, for example by checking the cleaning for the vacuum applications at Nikhef. But because of the complexity in the processes, the timeline kept shifting, so we had to work as flexibly as possible to match product availability. The ETpathfinder is a unique project, in which I consider it an honor to have been able to make a small contribution. But then again, small details is exactly what we are great at!"